Features:

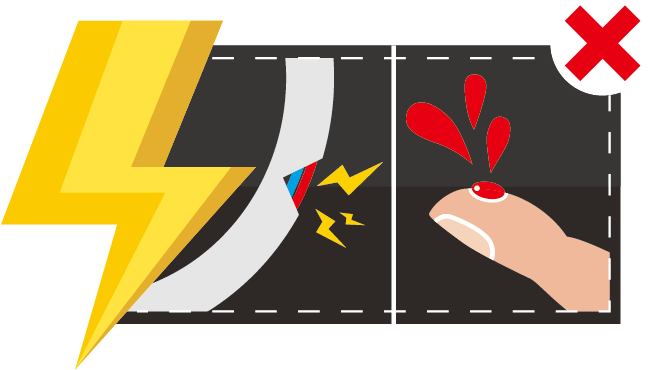

SAFETYPunch a perfect clean hole without any burrs.

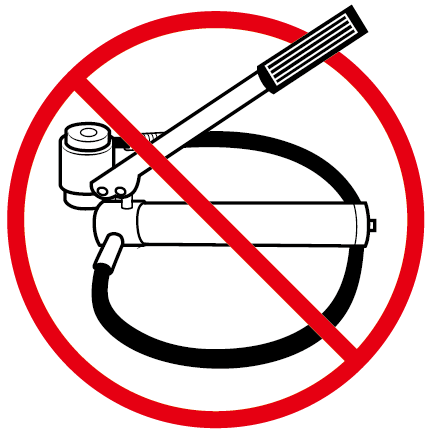

•A hand-powered hydraulic pump is much heavier and bulkier.

•LIGHTWEIGHT tools & perform tasks easier.

•To avoid sharp metal burrs can create an enormous injury risk for operators.

•To prevent the cable sheath from being cut by sharp metal edges.

Application:

•Punch round holes in sheet steel.

•Ideal for electricity controlling boxes, panels.

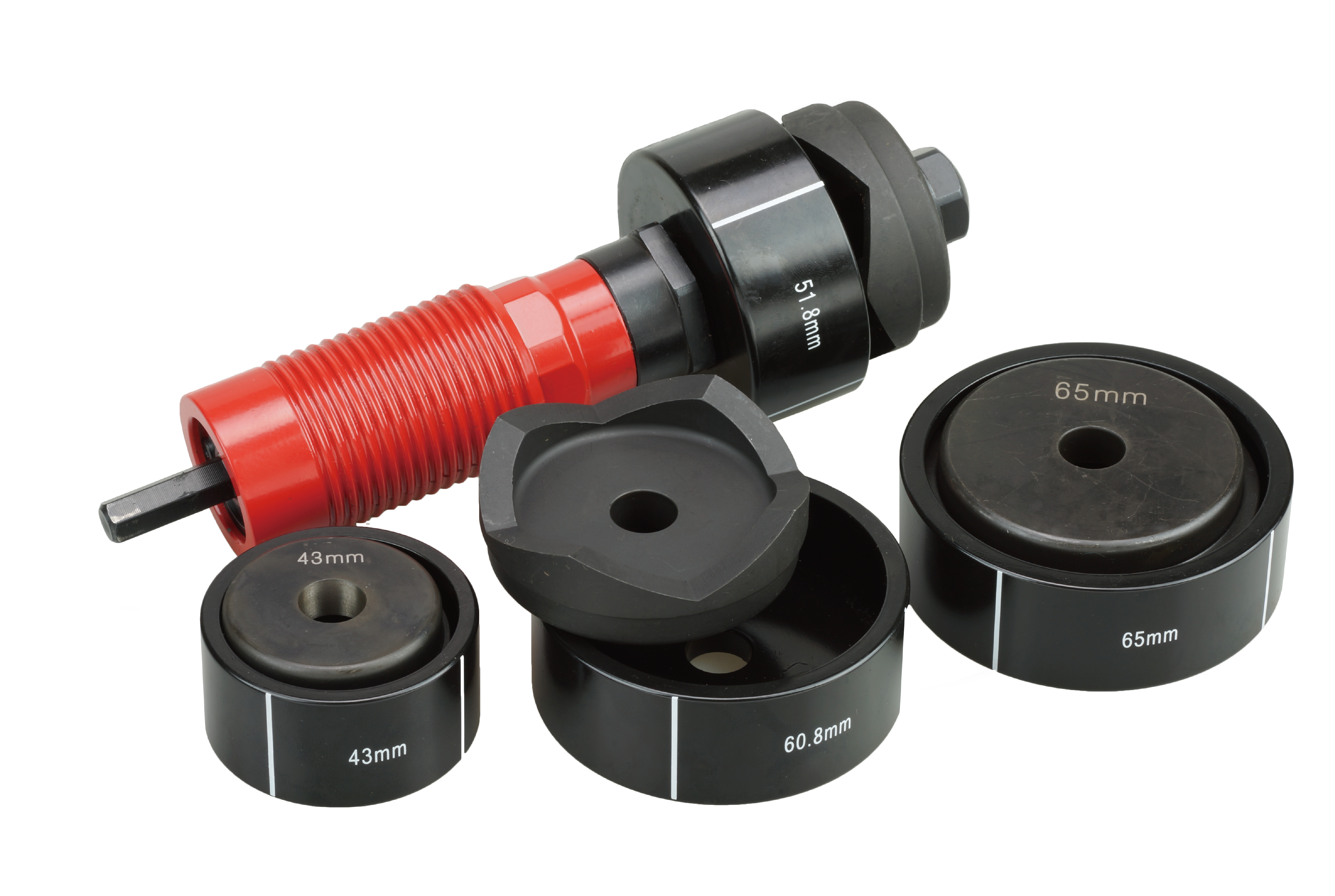

Knockout Punch Set (For Round Hole)

•Punch round holes in sheet metal. Ideal for electricity controlling boxes, panels.

•Safety- Punch a perfect clean round hole without any burrs.

•Cutting capacity: 1.2mm stainless steel ; 1.6mm mild steel

•Lightweight tools and perform tasks easier.

•For use with 14.4V or the higher voltage impact driver.(Torque range 120~150Nm)

USAGE INSTRUCTIONS (Round Hole)

STEP 1

Drill a φ13mm (MIN) pilot hole with a drill bit.

STEP 2

Switch the impact driver to the reverse position, extend the bolt to the longest length UNTIL IT MAKES A RATTLING SOUND.

Warming: STRICTLY PROHIBIT INSTALL THE MOLD FOR PUNCH WHEN THE DRIVING BOLT IS NOT FULLY EXTENDED!!

STEP 3

Fit the required size of die onto the bolt and insert the bolt into the pilot hole.

Thread the set nut onto the bolt and hand-tighten it

UNTIL SNUG.

Warming: STRICTLY PROHIBIT INSTALL THE MOLD FOR PUNCH WHEN THE DRIVING BOLT IS NOT FULLY EXTENDED!!

STEP 4

Turn the bolt with an impact driver; this pulls the punch toward the die. Keep turning until the punch passing through the material.

(Suggestion: Work with 14.4V or the higher voltage impact driver, Torque range 120~150Nm)

STEP 5

Separate the bolt and punch and remove the little ring of waste material inside the die.

**When idling occurs during punching, STOP the operation immediately and exclude the following conditions, which may cause idling:

(A) Whether the workpiece within the cutting capacity

(B) Whether the punch die/cutting surface wore

(C) Whether the punch die, bolt and set nut fit in the correct position

(D) The power tool is out of power or the torque is less than 110Nm

**Important Note**

Defects or damage caused by improper installation or use is not covered in the warranty.

Specification:

•Punch dies: Ø43、51.8、60.8、65mm, material: SKD-61

•Note: Require two-step punching for cutting a φ65mm hole

Step 1 - punch a Ø43mm hole

Step 2 - enlarge hole with a Ø65mm Punch die

•Ø12.3mm bearing driving bolt with 19mm set nut

Bolt: SCM-415; Body: Aluminum alloy ADC-12

•Extra 19mm set nut

•Adaptor: 1/4" Hex Shank, 8*L45mm

•PS insert (1.45mmT) + PP box (26x18x5cm)

< Back